Automation is a key aspect of modern manufacturing, and it has transformed the way products are assembled and manufactured. Despite the numerous benefits of automation, there are still many product assembly tasks that are performed manually. In this blog post, we will explore some of the reasons why we aren't automating more product assembly tasks and discuss the potential benefits of doing so.

One reason why we aren't automating more product assembly tasks is the upfront cost of automation. Automating a production line can be expensive, as it requires the purchase of customized equipment and the training of employees to operate and maintain it. This can be a significant investment for companies, especially small and medium-sized enterprises that lack the resources to invest in automation.

Another reason is a lack of available technology. While automation has come a long way in recent years, there are still many product assembly tasks that cannot be efficiently automated due to technological limitations. For example, tasks that require a high level of dexterity or precision, such as wiring, are often not suitable for automation.

Additionally, there may be regulatory or safety concerns that prevent companies from automating certain tasks. For example, there may be regulations in place that require certain tasks to be performed by humans, or there may be concerns about the safety of employees working alongside automation.

Despite these challenges, recent innovations have offered new opportunities to automate product assembly tasks. Recent technical advancements have continued to increase the efficiency and productivity of automation, as machines can work faster and more accurately than humans. This can lead to cost savings and faster time to break-even for companies, as they can produce more products in less time and with fewer errors.

Automation can also be sold through leasing models where manufacturers pay a lower cost for automation on a quarterly or even hourly basis. As a result, manufacturers that previously couldn’t pay high upfront costs for automation can now pay for automation as they would labor expenses.

Automation can also improve the quality of products, as machines can be programmed to perform tasks with a high level of precision and consistency. This can help to reduce defects and improve customer satisfaction.

Finally, in our current tight labor market environment, automation has the potential to free up human workers to focus on higher-value tasks, such as problem-solving, design, and innovation. This can help to increase the competitiveness of companies and lead to the development of new and innovative products.

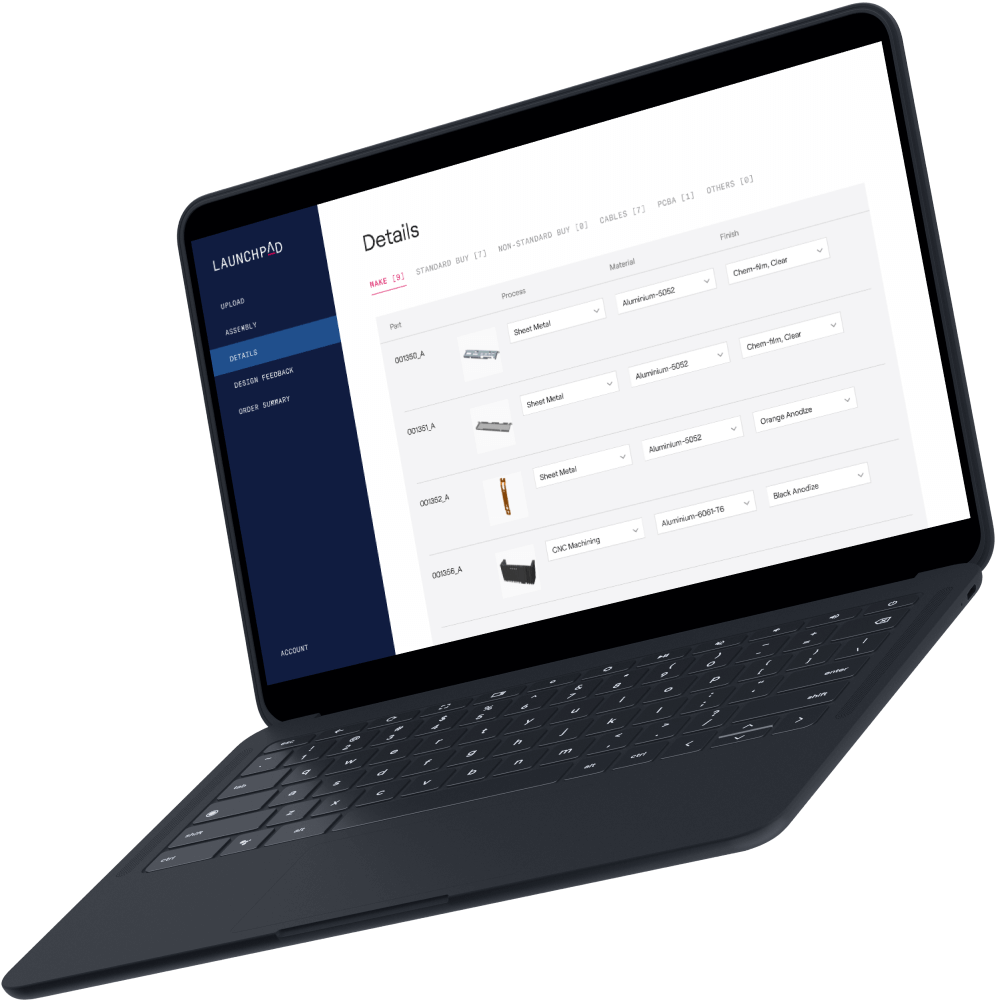

In conclusion, while there are challenges to automating more product assembly tasks, there are also significant potential benefits. Launchpad has been working with customers both domestic and abroad to apply our flexible automation solution to product assembly tasks that were otherwise inefficient to automate. Through this work we have helped customers increase efficiency, improve product quality, and free up human workers to focus on higher-value tasks. Make sure to check out our Digitool solution here or reach out for additional information.