Complete manufacturing

on demand

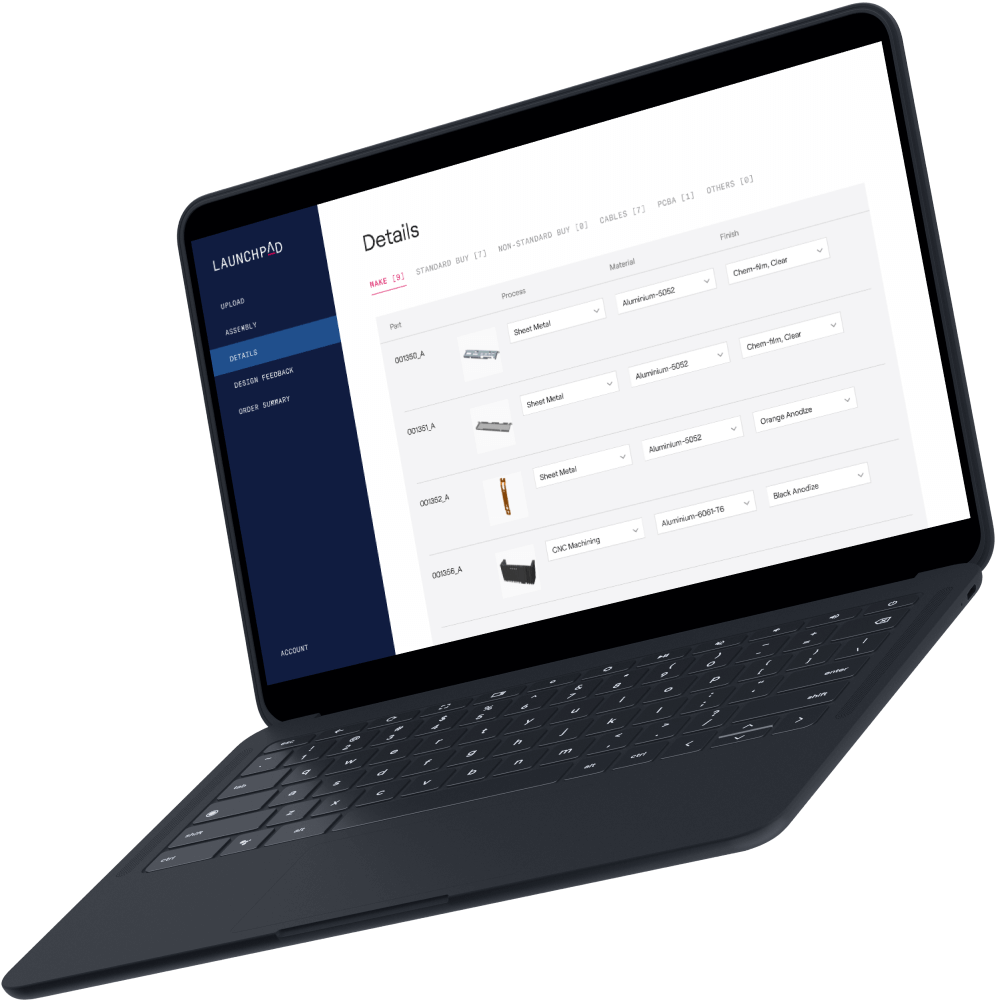

Launchpad uses advanced software to recognize parts, realize the most efficient assembly process, and provide a quote to fully manufacture your entire product.

Our automated on-demand manufacturing process reduces time, cost and headaches

Share your CAD file, desired unit volume, and any additional metadata such as inspection or surface finishes.

In real-time, Launchpad creates a quote and estimates lead time by autonomously sourcing components and assembly via our network of qualified suppliers and contract manufacturers.

If you like what you see then you provide approval and manufacturing begins.

Finished products are inspected, tested, packaged, and delivered to you.

Launchpad solves traditional manufacturing issues by providing a solution for building low volume products without a substantial investment

Some manufacturers aren’t willing to give low-volume orders the time of day. At Launchpad, we recognize your prototype could eventually change the world.

Like you, we have felt the pain of lost time waiting for vendor quotes. Providing an instant quote eliminates uncertainty so your team can start the delivery process ahead of schedule.

We visit each of our contract manufacturers to verify they can do what they claim and hit the quality standards you expect.

Traditional, offshore approaches to manufacturing are slow, costly and especially difficult for low volume manufacturing

Large overseas contract manufacturers require minimum order sizes (tens or hundreds of thousands of units) and cost upwards of millions of dollars.

Contract Manufacturers have limited tools to understand manufacturing challenges inherent to your new product design. Launchpad changes this.

Communicating across language, culture and time zone differences can result in lower manufacturing quality and unexpected costs.

Traditional, offshore approaches to manfuacturing are slow, costly and especially difficult for low volume manufacturing

Large overseas contract manufacturers require minimum order sizes (tens or hundreds of thousands of units) and cost upwards of millions of dollars.

Contract manufacturers often don’t give the attention you need to deliver well designed products.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Cras et vestibulum tellus dictum et amet non..

Shorten your supply chain with Launchpad

Learn more about our company

Meet the team behind Launchpad and learn more about our vision for the future of manufacturing.