In the rapidly evolving manufacturing landscape, automation integration has become pivotal to revolutionizing assembly processes. With the potential to enhance efficiency, ensure consistent quality, and streamline production, the question arises: When is the ideal time to consider automating manufacturing assembly tasks?

Understanding the Need for Automation

Automation introduces a level of consistency and precision that surpasses human capabilities. In the correct environment, automation can reduce manufacturing cost and production risk. Tasks performed by robots are executed with unwavering accuracy, minimizing errors and ensuring uniform quality across production lines.

While the initial investment in automation can seem daunting, it is essential to consider the long-term cost-efficiencies. With proper analysis, systems often realize break-even on CapEx expenditures within 1 to 2 years. Also, many vendors now offer the option to lease automation, enabling immediate realization of cost-efficiencies. As a result, automation, once established, often proves to be more cost-efficient than labor-intensive processes.

Increased Production Demand: In scenarios where demand surges, production requirements intensify, and labor shortages exist, manual labor alone may not suffice. In tight labor markets, the only thing harder than finding qualified labor, is keeping qualified labor. Automation allows for increased production rates and scalability, meeting elevated demand without compromising quality or timelines.

Safety and Ergonomics: Automation isn't just about efficiency—it also prioritizes safety. Hazardous or physically straining tasks can be assigned to robots, ensuring a safer work environment for employees and reducing the risk of workplace injuries.

When to Consider Automation

Start with a stable production process. Consider automation once manufacturing of the product is understood and relaible production forecasts are in place. This allows better automation design and testing through working with actual parts as well as more accurate financial analysis to value the potential savings.

Tasks that involve repetition are prime candidates for automation. Robots excel at performing these tasks consistently without fatigue, ensuring a high level of productivity without compromising quality.

Industries demanding high precision and accuracy, such as electronics, pharmaceuticals, and aerospace, can benefit from automation. Robots can execute tasks with pinpoint accuracy, minimizing margin for error.

As businesses grow, so does the need for scalability. Automation streamlines processes to handle larger volumes efficiently, adapting to increasing market demand. With accurate forecasts manufacturers can look to align an automation solution 6 to 12 months prior to anticipated ramps to assure delivery of a scalable solution.

Embracing technological advancements is crucial to staying competitive. Manufacturers must continually assess their processes and leverage the latest automation technologies to improve efficiency and maintain relevance in the industry.

First Steps Toward Automation

Conduct a comprehensive evaluation of existing assembly methods. Identify areas where automation could enhance efficiency and quality while streamlining production.

Pinpoint specific tasks within the manufacturing process that are suitable for automation. Start with smaller, manageable tasks to familiarize the team with automated systems.

Perform a detailed cost-benefit analysis to determine automation feasibility and potential return on investment (ROI). This analysis helps in making informed decisions regarding implementation.

Research and select the right robotic solutions and software tailored to your manufacturing needs. Consider factors like compatibility, ease of integration, and long-term support.

Case Studies and Success Stories

Looking at real-world examples of successful implementation can provide valuable insights. Companies across various industries have realized improvement in efficiency, quality, and overall productivity after adopting automation.

Challenges and Considerations

While the benefits of automation are substantial, there are challenges to navigate. Initial costs, workforce concerns, and proper training and maintenance requirements must be addressed. Change management becomes crucial in helping the team adapt to the introduction of automated systems.

Conclusion

When applied properly, automation represents a transformative force in modern manufacturing. The decision to embrace it must be informed or adoption can set a team back for months. Evaluating the need for automation, identifying suitable tasks, conducting thorough analysis, and addressing challenges are pivotal steps toward successful implementation.

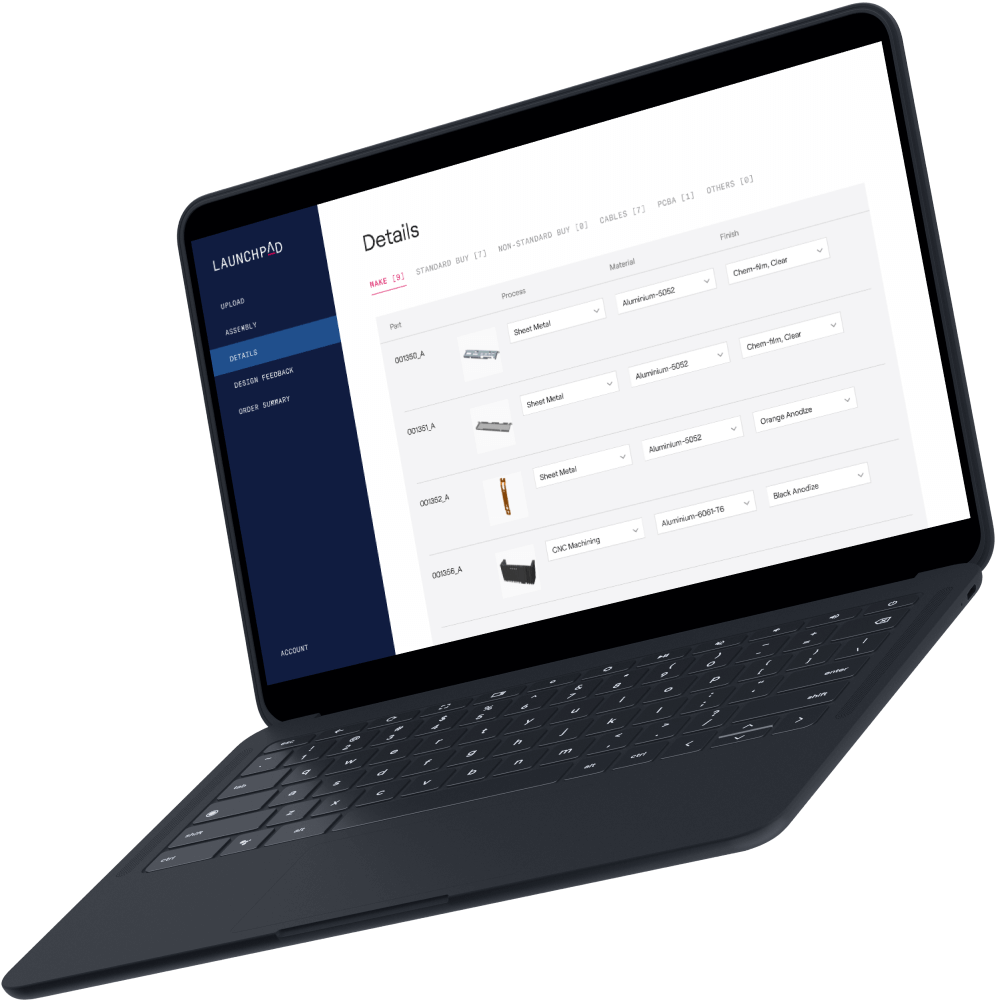

In a landscape where adaptability is key, automation stands as a cornerstone for manufacturing efficiency and competitiveness. At Launchpad, we are working with manufacturers to deliver new and more flexible automation solutions that support a wide variety of assembly applications. Check out our Digitool solution here and reach out for any additional information. Embrace the possibilities automation offers, and propel your manufacturing processes into a future of innovation and efficiency.