Reshoring manufacturing is a term used to describe the process of returning the manufacture of domestic products from another country back to the country where sales of the business' products are based. For a strong understanding of the definition of reshoring, it's important to begin by noting the difference between the terms "offshoring" and "outsourcing".

We will explain those terms shortly, as well as the terms "nearsourcing" and "insourcing". But first, we'll take a look at the history of offshoring. We'll close by covering addressing the benefits of reshoring in the US, and how companies can overcome challenges in making the switch.

A Brief History of Offshoring

How did so much of manufacturing end up being taken offshore? Offshoring, the practice of moving a company's manufacturing facilities to another country, began in earnest in the late 1970s. Prominent companies started the trend of offshoring manufacturing, to support the goal of maximizing shareholder profits.

Lowered labor costs and lessened need to meet environmental regulations enabled many manufacturers to generate significant profits, even after subtracting the huge costs of shipping raw materials for manufacturing, and finished goods internationally.

At that time, offshoring made sense. Today, many companies are realizing reshoring may be a better choice.

Offshoring vs. Outsourcing

The two related terms, offshoring and outsourcing, are often misunderstood.

Outsourcing was first recognized as a business strategy in 1989. Businesses seek to obtain goods and services from outside sources, other companies which often specialize in the services, rather than produce them in-house are said to be outsourcing.

Companies are said to be outsourcing no matter where the sources are located, whether within the company's own home country, in a neighboring country, or at an overseas site. Outsourcing goods and services within the same country that is where a company is located, doesn't detract from the nation's economy.

Offshoring can be a type of outsourcing, but not always. Sometimes companies will move facilities to another country without bringing on a third party to do the work. The word offshoring, in the US, is regularly associated with the movement of American manufacturing facilities off of the US shore and onshore in another country, often China. But the term offshoring shouldn't be taken so literally.

The definition of offshoring is the process of relocating business operations to another country as a means of minimizing costs. The site of the outsourced manufacturing could be a neighboring country. It doesn't have to be a nation across the ocean.

Offshoring is frequently undertaken in the interest of reducing labor costs. But it's done for other reasons as well. Supporters say outsourcing optimizes efficiency and supports global, free-market economics. Detractors complain that it triggers losses of domestic manufacturing jobs.

Nearshoring and Insourcing

These two terms are also related.

Nearshoring means locating a business' manufacturing operations near where its end products are sold. This practice offers the obvious advantage of reduced shipping costs.

Insourcing occurs when: "a business practice in which work that would otherwise have been contracted out is performed in house". Insourcing sometimes requires specialized staff members to be brought in to a company to complete a manufacturing process on premise. This is in contrast to sending the work out - "outsourcing" - to a company that specializes in the process.

The Benefits of Reshoring

Why are companies reshoring manufacturing? Conditions have changed since the 1970s. Costs are increasing in developing countries. International trade policies are uncertain and unstable. Supply chain issues are challenging workflows. Advances in technology have enabled greater automation. Reshoring makes economic sense for a growing number of US manufacturers.

The benefits of reshoring today are many. The economy of the home country of a reshoring company is bolstered when resources, assets, and jobs return.

Perks of reshoring include:

- Lessened need for costly, profit-draining freight expenses

- Capability to fulfill the growing demand for locally made products.

- Optimization of workflow in a way that enables production of more specialized products with less capital invested.

- The ability to be self-reliant, as a country, during a global crisis.

- Shorter waiting periods for parts and components.

- Reduced need to carry an extensive inventory.

- Lessened logistics issues, risks, and expenses.

- Less need for extensive inventories with carrying costs.

- Flexibility when revising manufacturing processes.

- Greater control of intellectual property.

- Less emphasis on larger batch sizes.

- Reshoring will benefit a business' home country.

Reshoring in the US

Reshoring U.S. manufacturing could be the wave of the future. How many companies will be reshoring in the U.S. in the coming months and years?

A Thomas survey in April 2020 of 878 North American manufacturing and industrial sector professionals reportedly puts the number at 64 percent.

Many companies that produce or utilize the following types of products are reshoring manufacturing, including:

- Personal protective equipment (PPE).

- Rare earth metals.

- Transportation equipment.

- Chemicals.

- Biotechology

- Computers and electronics.

- Automotive and aerospace products.

- Steel and aluminum.

- Manufactured parts requiring processes like die-cast mold tooling, plastic injection molding, CNC machining.

- Intricately made, complex manufactured parts.

Reshoring is Changing US Manufacturing

"Companies are increasingly establishing production in proximity to demand." That was beginning to happen even before the pandemic taught us all lessons about supply chains and made us consider the security problems that may result from offshoring the manufacture of so many critical products.

The reshoring trend that had already begun, and which escalated in 2020, continues to boom in 2021.

There is no doubt reshoring is changing US manufacturing strategies and considerations. Companies reshoring their manufacturing operations will increasingly require digitally fluent workforces. Good paying jobs will be created in the US. The need for cheap labor - which originally sent manufacturing offshore, will decrease. Already technology is facilitating profitability. That trend is expected to continue.

Reshoring can help boost the US economy, ensure supply chain stability and support national security. There are a few challenges involved in reshoring. Like the cost of moving operations initially, skills gaps, and the current labor shortage.

But increasing AI technology options and outsourced manufacturing providers in the US bring solutions to those challenges by delivering efficient, innovative, cost-effective manufacturing services. These new technologies can help rebuild American manufacturing.

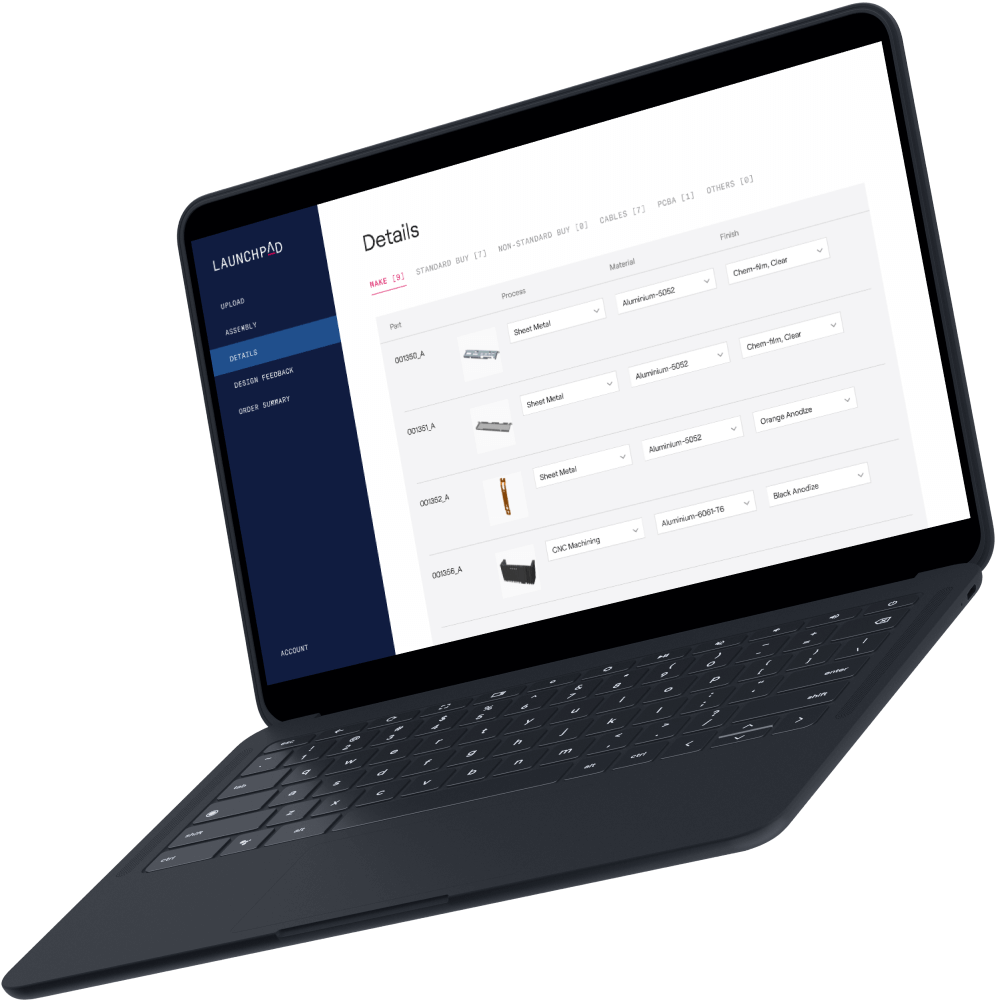

Launchpad supports reshoring by providing AI powered, automated technologies for design, procurement, and manufacturing processes. Contact us to learn more about how innovative manufacturing processes are revolutionizing production, and how we help clients seeking cost-effective manufacturing capabilities in the US.